NACHHALTIGKEIT TRIFFT AUF INNOVATION

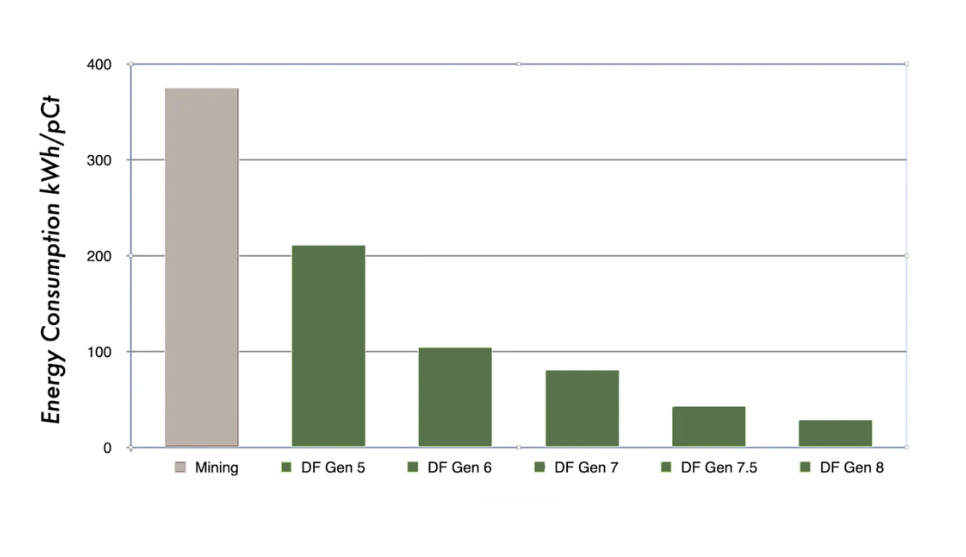

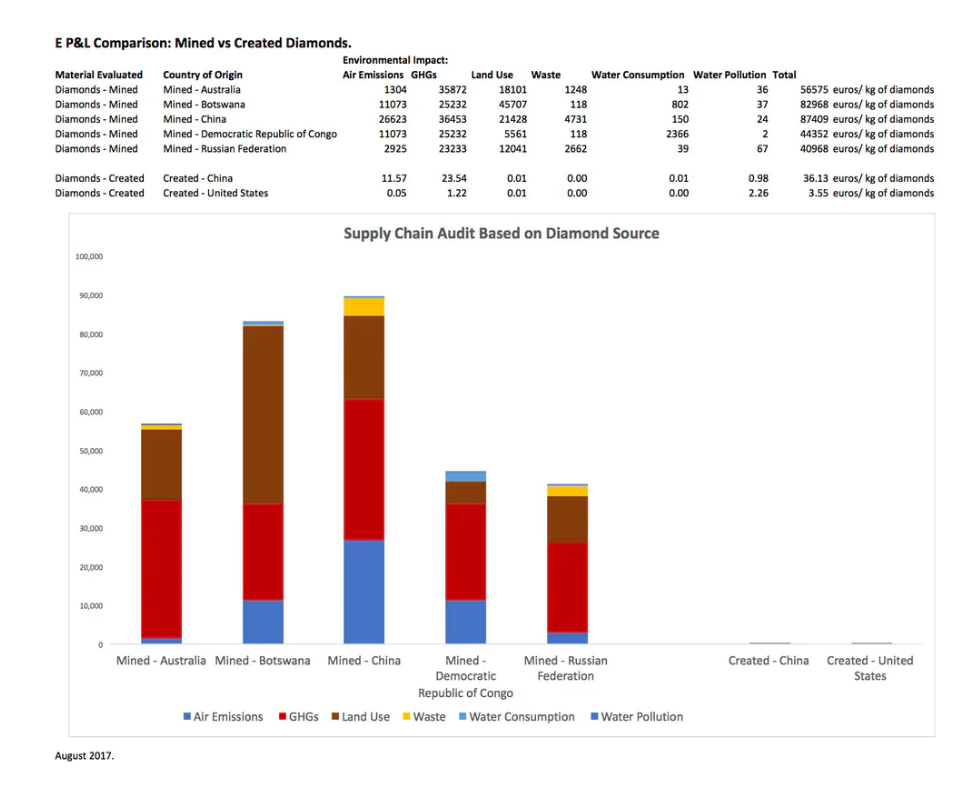

Dank des äußerst energieeffizienten Herstellungsverfahrens der Diamond Foundry ist der MANUFAKTURDIAMANT® ein einzigartiger, nachweislich nachhaltiger und hochwertiger Diamant.

THE HOCHMODERNER FERTIGUNGSPROZESS

Zur Herstellung seiner Rohdiamanten nutzt Diamond Foundry die CVD-Technologie (Chemical Vapor Deposition, chemische Gasphasenabscheidung). Bei diesem Verfahren wird ein Plasma erzeugt, in dem sich Kohlenstoffatome frei an das Kristallgitter eines sogenannten „Diamantkeims” anlagern können, wodurch dieser Atom für Atom vergrößert wird, bis ein Diamant in Edelsteinqualität entsteht.

EMISSIONSFREIE PRODUKTION DURCH REINE WASSERKRAFT

Die Hightech-Produktionsstätte in Wenatchee, Washington, wird emissionsfrei betrieben. Die Diamond Foundry nutzt ausschließlich die Wasserkraft des Columbia River zur Herstellung der Rohdiamanten. Sie arbeitet eng mit den Verantwortlichen vor Ort zusammen, um sicherzustellen, dass auch für zukünftige Produktionserweiterungen zu 100 % erneuerbare Energien genutzt werden können.